Introduction to stainless steel grades

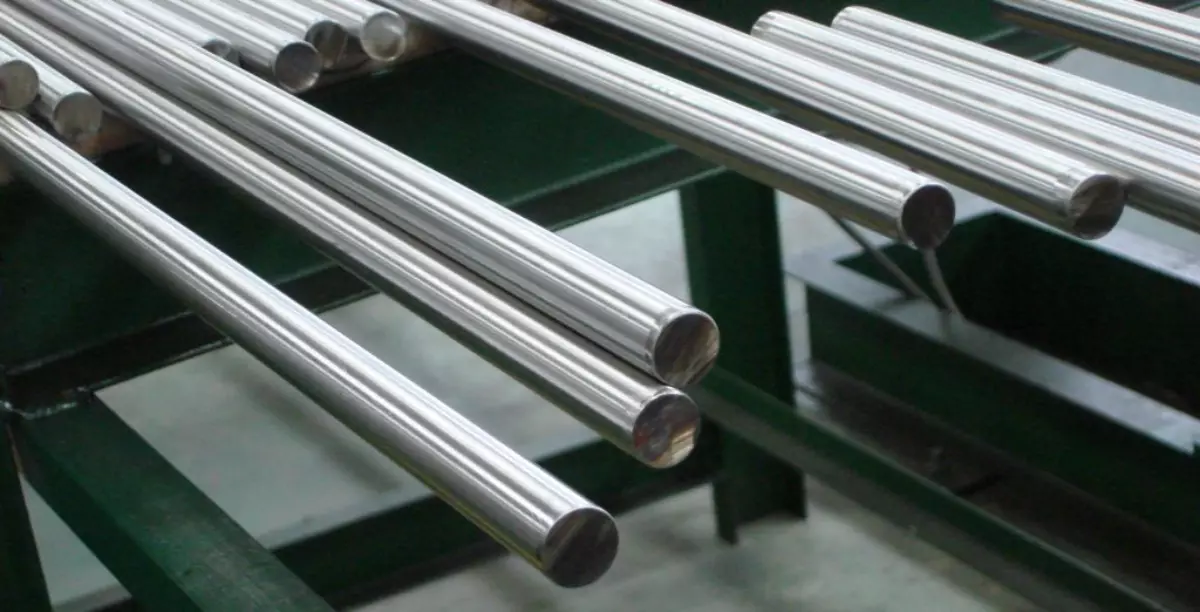

Stainless steel is renowned for its corrosion resistance, strength, and versatility.

This unique material is composed primarily of iron, with a minimum of 10.5% chromium, which forms a protective layer on the surface. Depending on the grade, stainless steel can also contain varying amounts of carbon, silicon, manganese, and other elements to enhance specific properties.

The different grades of stainless steel are classified based on their microstructure, chemical composition, and mechanical properties. These variations enable stainless steel to be tailored for a wide range of applications, from kitchen utensils to industrial machinery. Understanding the distinctions between these grades is crucial for selecting the right material for a given application.

In this article, we will explore some of the most common grades of stainless steel and their typical uses. We will cover austenitic, ferritic, martensitic, duplex, and precipitation hardening stainless steels, detailing their properties and practical applications in various industries.

Austenitic stainless steels

Austenitic stainless steels are the most widely used category, known for their excellent corrosion resistance and formability. These steels contain high levels of chromium and nickel, making them non-magnetic and highly resistant to rust. Common grades in this category include 304 and 316 stainless steel.

Grade 304 stainless steel is the most versatile and widely used. It is ideal for a range of applications, including kitchen appliances, chemical processing equipment, and automotive components. Its excellent weldability and formability make it a favorite in many manufacturing processes.

Grade 316 stainless steel contains molybdenum, which enhances its corrosion resistance, particularly against chlorides and other industrial solvents. This makes it suitable for use in harsh environments such as marine applications, chemical plants, and medical devices. The added durability of 316 stainless steel makes it a premium choice where enhanced performance is required.

Ferritic stainless steels

Ferritic stainless steels are characterized by their high chromium content and low carbon levels, making them magnetic and providing good resistance to stress corrosion cracking. They are generally less expensive than austenitic grades and offer moderate corrosion resistance and good mechanical properties.

Common grades in this category include 409 and 430 stainless steel. Grade 409 is often used in automotive exhaust systems due to its ability to withstand high temperatures and resistance to oxidation. It offers a cost-effective solution without sacrificing essential performance qualities.

Grade 430 stainless steel is widely used in the kitchenware and appliance industries. Its excellent resistance to nitric acid and organic acids makes it suitable for applications involving food and beverage processing. Although it is less formable than austenitic grades, its affordability and adequate performance make it a popular choice for household items.

Martensitic stainless steels

Martensitic stainless steels are known for their high strength and hardness, achieved through heat treatment. These steels contain higher carbon levels compared to austenitic and ferritic grades, which contribute to their ability to be hardened. Common grades include 410 and 420 stainless steel.

Grade 410 stainless steel is used in applications where high strength and moderate corrosion resistance are required. It is often found in cutlery, turbine blades, and surgical instruments. Its ability to be heat-treated to various hardness levels makes it versatile for different uses.

Grade 420 stainless steel, also known as “cutlery grade” stainless steel, is used extensively in knife blades and surgical instruments. It can be hardened to a higher degree than 410, providing excellent edge retention and wear resistance. Its balance of hardness and corrosion resistance makes it ideal for precision tools.

Duplex stainless steels

Duplex stainless steels have a mixed microstructure of austenite and ferrite, providing a balance of strength and corrosion resistance. These steels are known for their excellent resistance to stress corrosion cracking and superior mechanical properties compared to standard austenitic grades.

Common grades include 2205 and 2507 stainless steel. Grade 2205 is widely used in chemical processing, oil and gas, and marine applications. Its combination of high strength and resistance to chloride stress corrosion makes it suitable for challenging environments.

Grade 2507, also known as super duplex stainless steel, offers even greater strength and corrosion resistance than 2205. It is used in applications that require exceptional durability, such as offshore platforms, desalination plants, and chemical processing equipment. The superior performance of super duplex grades makes them ideal for extreme conditions.

Precipitation hardening stainless steels

Precipitation hardening stainless steels, also known as PH stainless steels, can be heat-treated to achieve high strength and hardness. These steels contain alloying elements such as copper, niobium, and aluminum, which enhance their mechanical properties through precipitation hardening.

Common grades include 17-4 PH and 15-5 PH stainless steel. Grade 17-4 PH is used in aerospace, chemical processing, and food processing industries due to its high strength, good corrosion resistance, and excellent mechanical properties. It is particularly valued for its ease of fabrication and high fatigue resistance.

Grade 15-5 PH stainless steel offers similar properties to 17-4 PH but with improved toughness. It is used in applications requiring high reliability and performance, such as aircraft components, medical devices, and high-pressure fittings. The enhanced toughness and corrosion resistance of 15-5 PH make it a preferred choice for critical applications.

Understanding the different grades of stainless steel and their specific properties is essential for selecting the right material for various applications. Each grade offers unique advantages, from the excellent corrosion resistance of austenitic steels to the high strength of martensitic and precipitation hardening steels – rollsteel.eu.

Choosing the correct stainless steel grade ensures optimal performance, longevity, and cost-effectiveness in the intended application. Whether it’s for household appliances, industrial machinery, or medical devices, there is a stainless steel grade designed to meet the specific demands of each use case.

As industries continue to evolve and new technologies emerge, the versatility and reliability of stainless steel will remain indispensable. By understanding the distinct characteristics of each grade, manufacturers and engineers can make informed decisions to achieve the best possible outcomes in their projects.